Centrifugal fans play a critical role in industrial processes thanks to their efficient ventilation and cooling performance. However, the drive method directly impacts both efficiency and service life. This article explains the three main drive types of centrifugal fans, how to select the right one for your application, and introduces a high-quality solution to boost productivity.

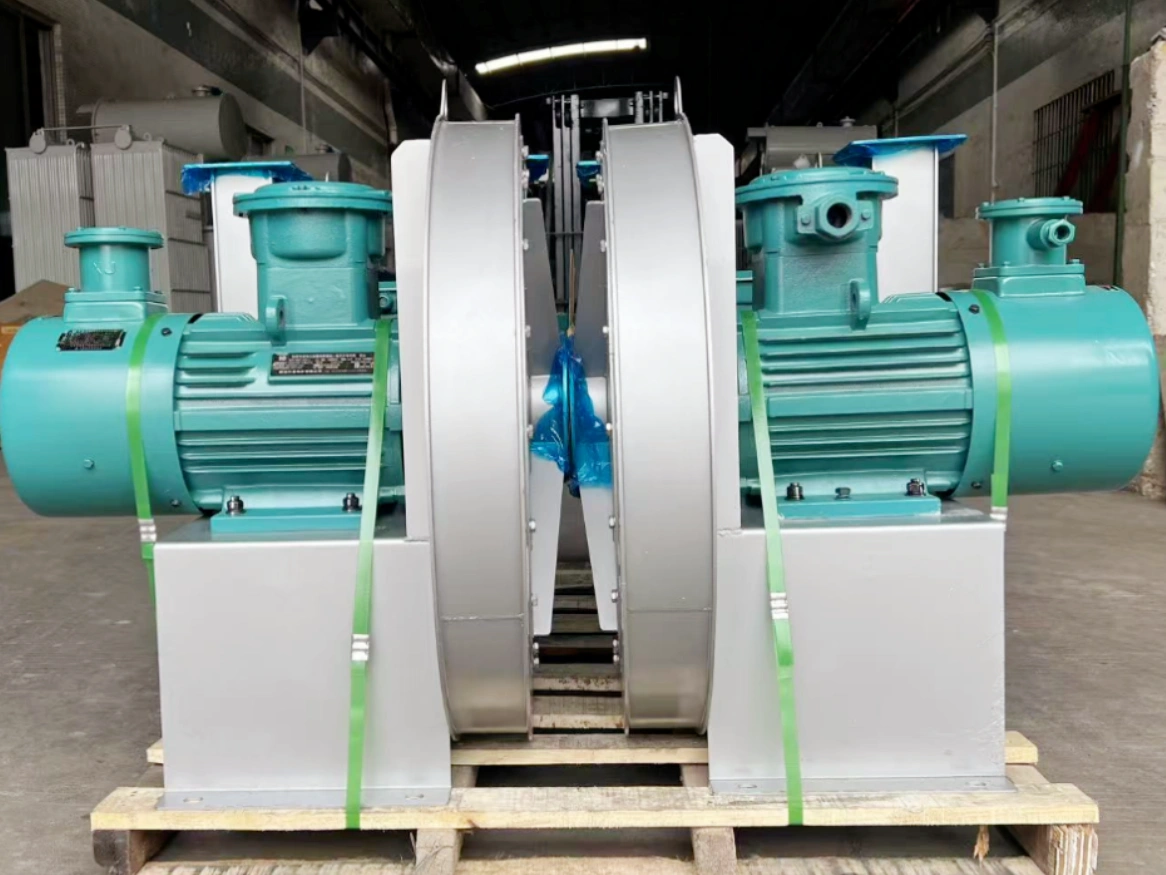

Direct-Drive Configuration (Type A)

In this setup, the impeller is mounted directly on the motor shaft with no intermediate components. It’s ideal for compact spaces and low-power requirements, such as small workshops or laboratories. The design is simple, highly efficient, and requires minimal maintenance, but the fixed motor speed limits airflow adjustment.

Belt-Drive Configuration (Types B, C, E, F)

Belt-driven fans offer flexibility in speed control, making them suitable for applications that demand variable airflow, such as drying or tunnel ventilation. These models support medium to high power levels and are cost-effective. However, they require regular belt maintenance and experience some energy loss compared to direct-drive fans.

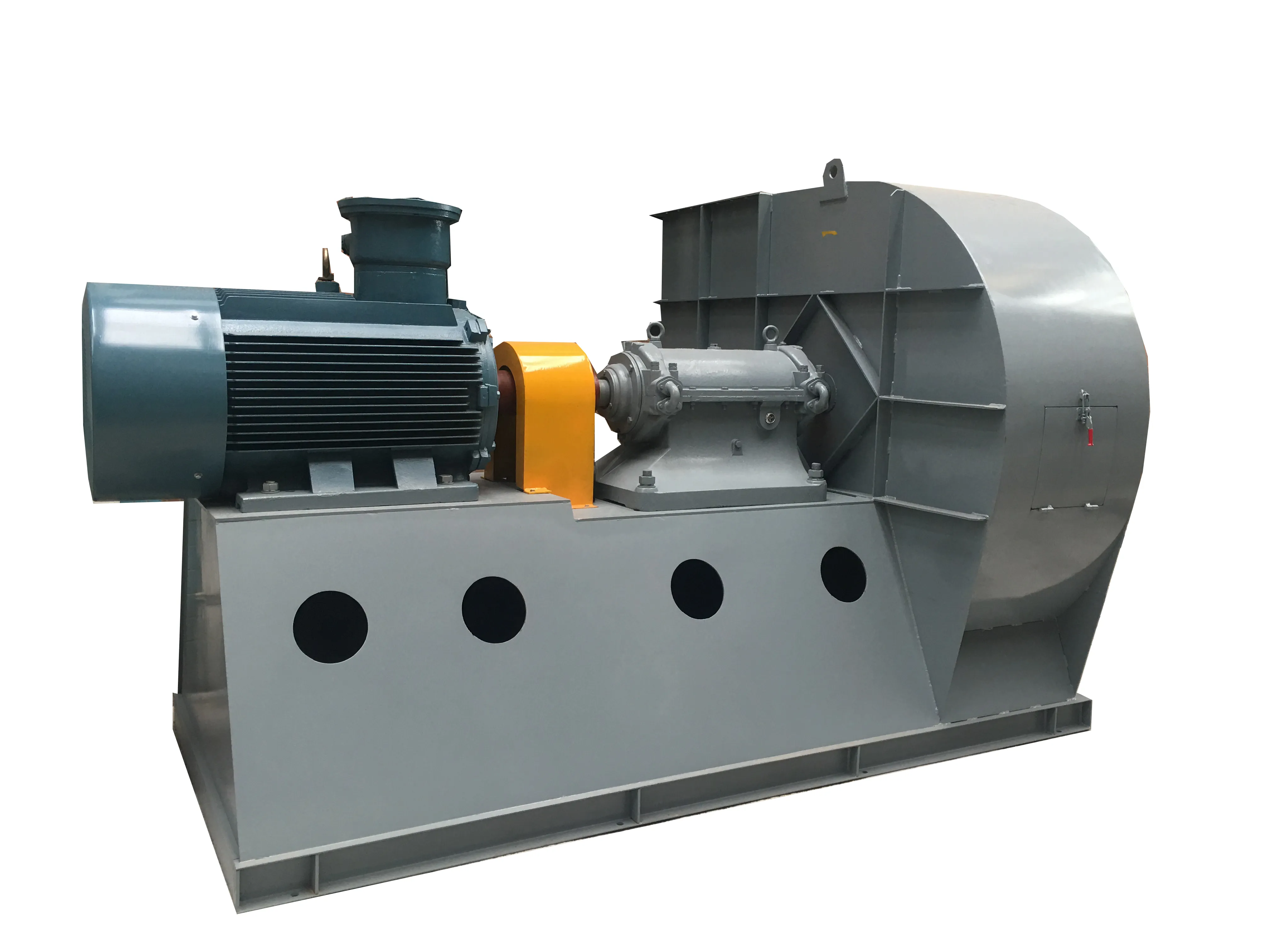

Coupling-Drive Configuration (Type D)

This method connects the motor and fan through a coupling for stable transmission. It is commonly used in high-power industrial environments such as metallurgy or chemical plants. Coupling-drive fans are robust, durable, and efficient, though installation precision is critical and costs are higher.

How to Choose the Right Drive Method

• Match power requirements: direct drive for low power, belt drive for medium power, coupling drive for high power.

• Consider space constraints: direct or compact belt drive fits tight spaces.

• Assess airflow adjustment needs: belt drive offers flexible speed control.

• Factor in maintenance costs: direct and coupling drives require less frequent servicing.

Custom Solutions from YueYu Machinery

With years of expertise in fan manufacturing, Yueyu Machinery provides centrifugal fans in all major drive configurations to suit various industrial applications.

Advantages of Yueyu fans include:

• Energy-efficient design, reducing power consumption by up to 15%–20% compared to standard models.

• Low-noise operation with sound levels as low as 75 dB.

• Fully customizable solutions, including drive type, blade angle, and high-temperature or corrosion-resistant materials.