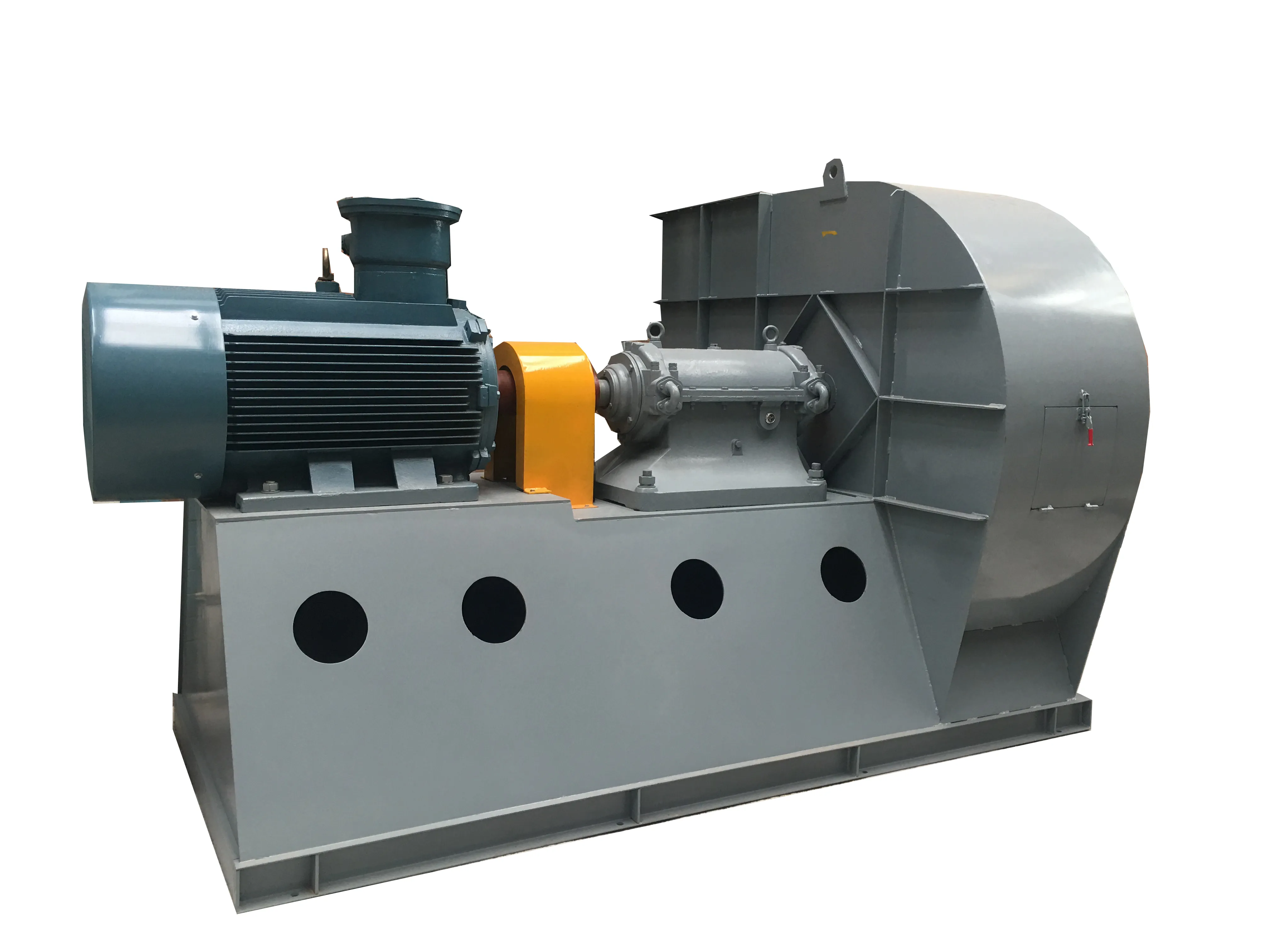

In industrial ventilation systems, environmental protection projects, boiler applications, and manufacturing facilities, centrifugal fans play a vital role. However, as operating hours increase, fan noise often becomes a major concern for users.

Excessive noise not only affects the working environment but can also indicate vibration issues, accelerate bearing wear, reduce equipment lifespan, and even lead to non-compliance with occupational health and environmental standards.

So, why do centrifugal fans generate noise, and how can it be effectively reduced?

This article provides a professional and practical guide to centrifugal fan noise sources and 7 proven noise reduction solutions.

1. Main Sources of Noise in Centrifugal Fans

Centrifugal fan noise generally comes from three primary sources:

1) Aerodynamic Noise (Primary Source)

Generated by high-speed airflow, turbulence, and air impact on fan blades. This is the most dominant noise source.

2) Mechanical Noise

Caused by bearings, motors, couplings, and mechanical vibration.

3) Structural and System Noise

Includes casing resonance, foundation vibration, and secondary noise generated by poorly designed duct systems.

Effective noise reduction requires addressing these sources systematically.

2. 7 Key Methods to Reduce Centrifugal Fan Noise

1️⃣ Optimize Impeller Design

The impeller is the “heart” of a centrifugal fan, and its design has a direct impact on noise levels.

Key optimization measures include:

- Using backward-curved blades for smoother airflow

- Optimizing blade quantity to reduce turbulence

- Applying airfoil blade profiles

- Optimizing the clearance between impeller and volute

- Improving dynamic balancing accuracy

Smoother airflow = lower aerodynamic noise.

2️⃣ Install Inlet and Outlet Silencers

Installing silencers at the fan inlet or outlet is one of the most effective ways to reduce airflow noise.

Common types include:

- Absorptive silencers

- Reactive silencers

- Hybrid (absorptive + reactive) silencers

Widely used in boiler fans, dust collection systems, industrial ventilation, and environmental protection projects.

3️⃣ Use Acoustic Enclosures

For applications with strict noise limits, installing a soundproof enclosure around the fan and motor can significantly reduce noise:

- Inner surfaces lined with sound-absorbing materials

- Reduces both aerodynamic and mechanical noise

- Typical noise reduction: 10–25 dB

Ideal for installations near offices, residential areas, or continuous-operation facilities.

4️⃣ Implement Vibration Isolation and Control

Vibration often amplifies noise. Proper vibration control can dramatically reduce sound levels:

- Install spring or rubber vibration isolators

- Reinforce fan foundations

- Precisely align couplings

- Use flexible connectors between fan and ductwork

Less vibration means less noise.

5️⃣ Optimize Duct Design to Reduce Secondary Noise

Poor duct design can generate additional noise even if the fan itself is quiet.

Recommended measures:

- Avoid sudden duct contractions or sharp bends

- Install straight duct sections at fan inlet and outlet

- Add duct silencers where necessary

- Improve airflow uniformity

Well-designed duct systems are essential for overall noise control.

6️⃣ Control Operating Conditions

When centrifugal fans operate beyond their design limits—such as excessive airflow, pressure, or rotational speed—noise levels increase significantly.

Suggestions:

- Use variable frequency drives

- Adjust dampers properly

- Ensure fan performance matches system resistance

Operating near the design point ensures lower noise and higher efficiency.

7️⃣ Use High-Quality Bearings and Precision Manufacturing

Mechanical noise often results from:

- Low-quality or worn bearings

- Poor lubrication

- Insufficient impeller balance accuracy

Solutions include:

Strict factory dynamic balancing tests

Using high-quality bearings

Implementing regular lubrication maintenance

Preventing dust buildup on impellers

3. Practical Benefits of Centrifugal Fan Noise Reduction

Effective noise control delivers multiple advantages:

✔ Improved workplace comfort

✔ Reduced noise pollution

✔ Extended fan service life

✔ Lower maintenance frequency

✔ Compliance with environmental and occupational standards

4. Yueyu Machinery’s Noise Reduction Solutions

As a professional industrial fan manufacturer, Yueyu Machinery offers:

- Low-noise centrifugal fan design and manufacturing

- Aerodynamic impeller optimization

- Integrated silencers and acoustic enclosures

- Complete fan system noise control solutions

- Technical consulting and on-site support

We provide not just equipment, but complete engineering solutions.

📞 Contact Yueyu Machinery

Phone: +86 13246303033

WhatsApp:+1 (408) 590 3985

Email: [email protected] ; [email protected]

Website: [www.yueyublower.com]