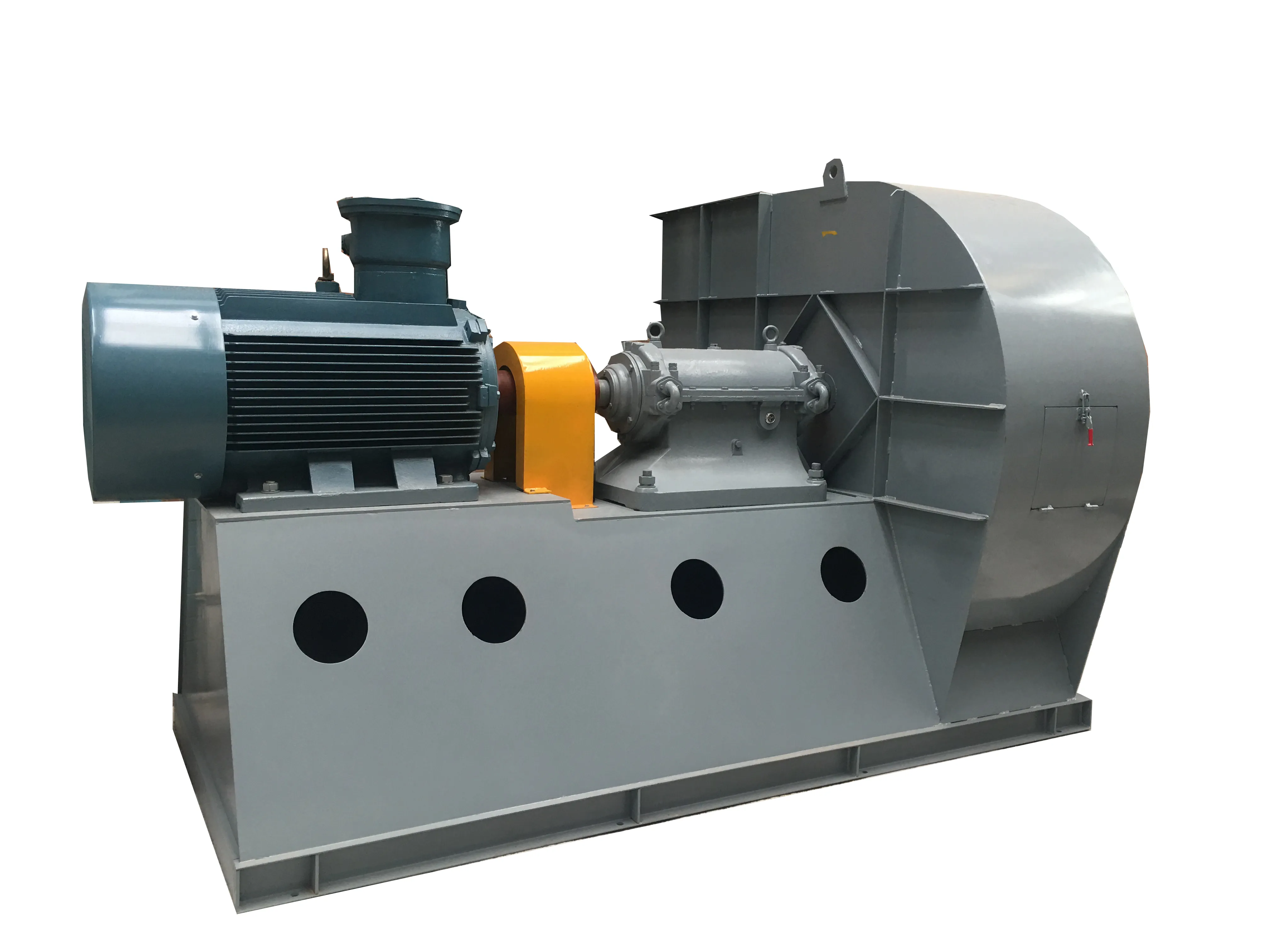

With the arrival of summer heat, centrifugal fans operating under heavy loads in industries like metallurgy, chemicals, and power generation are prone to performance degradation and component wear. Foshan Yueyu Machinery Equipment Co., Ltd., leveraging 20 years of industry experience, presents usage standards, maintenance priorities, and failure prevention solutions for centrifugal fans during high-temperature seasons to ensure stable summer operations.

I. Precautions for High-Temperature Environments

- Enhanced Cooling Systems

Ensure cooling fans on motor shafts function properly. Keep inlet/outlet water pipe interfaces on metal castings unobstructed to prevent motor overheating shutdowns. Recommendation: Install auxiliary cooling devices (e.g., axial fans) when ambient temperatures exceed 40°C. - Upgraded Lubrication Management

High temperatures reduce lubricant viscosity. Use high-temperature-resistant synthetic oils and shorten replacement cycles to 300–500 hours (standard: 800 hours). Monitor oil levels to prevent bearing wear due to insufficient lubrication. - Load Control Strategy

Balance airflow by adjusting inlet dampers and cold air valves to avoid motor overloads. Maintain operating power below 90% of the rated value and limit continuous runtime to ≤8 hours.

II. Daily/Bi-Shift Maintenance Checklists

- Vibration & Noise Inspection

Measure bearing vibrations with a vibrometer; halt operations if amplitude exceeds 4.5 mm/s. Use a stethoscope to detect impeller collisions or imbalance. - Sealing System Checks

Inspect shaft seals and flange joints for oil/gas leaks. High temperatures accelerate seal aging—replace immediately with high-temperature silicone seals if leakage occurs. - Filter Cleaning

Clean inlet filter dust daily to prevent airflow blockage (thoroughly wash if pressure differential >200 Pa).

III. Critical Periodic Maintenance (Monthly/Quarterly)

- Impeller Deep Maintenance

Remove accumulated dust monthly (especially on backward-inclined blades). Check corrosion on galvanized/cold-rolled steel plates; return for repair if rust coverage >10%. - Bearing System Maintenance

Quarterly measure bearing clearance; adjust if radial play >0.15 mm. Verify coupling alignment (deviation ≤0.05 mm). - Electrical System Inspection

Test motor insulation resistance (≥500 MΩ), clean dust in junction boxes, and install overload protection relays for high-temperature environments.

IV. Special High-Temperature Season Protections

- Explosion Prevention Protocol

For flammable gas transport: Monthly inspect explosion-proof junction boxes. Ensure impellers are aluminum/copper alloy (avoid spark risks from steel). - Extreme Weather Response

Before thunderstorms: Check grounding resistance (≤4 Ω). During typhoons: Reinforce base bolts for outdoor fans to prevent toppling. - Smart Monitoring Upgrades

Install IoT modules to track bearing temperature (alert: 85°C), vibration spectra, and current fluctuations for predictive maintenance.

Conclusion

Foshan Yueyu Machinery Equipment Co., Ltd. specializes in R&D and manufacturing of centrifugal fans, offering year-round maintenance services and technical support.

- Contact us today to discuss your requirements or request a quote!

- Phone: +86 13246303033

- Email: [email protected]

- Website: [www.yueyublower.com]