Chemical, Food & Pharma Equipment Solutions by Yueyu

Why Are High-Performance Fans Essential in Chemical, Food & Pharma Industries?

Chemical, food, and pharmaceutical production demands strict cleanroom standards, precise temperature and humidity control, and explosion-proof safety. Stable airflow is critical for processes like drying, gas transfer, and reactor ventilation, while regulations and cost pressures drive adoption of energy-efficient, high-performance centrifugal fans.

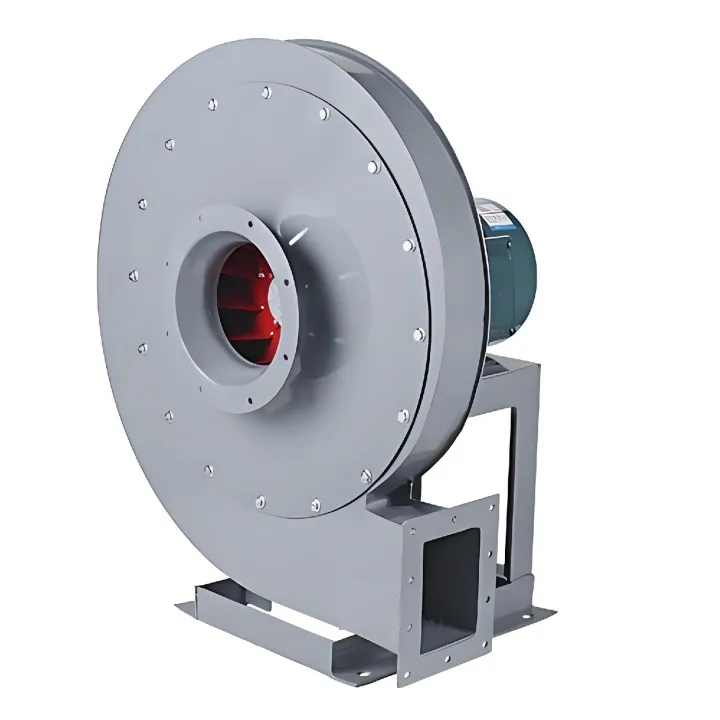

Yueyu Centrifugal Fans Meet Diverse Industrial Needs

● Chemical Industry

Explosion-Proof Ventilation: YYHP high-pressure centrifugal fans safely exhaust gases from reactors in flammable environments.

Waste Gas Treatment: Integrated with scrubbers and adsorption units to handle acidic gases and organic vapors.

● Food Industry

Drying Line Air Supply: Corrosion-resistant stainless steel fans provide constant hot airflow for dryers, preventing contamination.

Cleanroom Circulation: Low-noise fans maintain positive pressure in sterile areas, blocking external pollutants.

● Pharmaceutical Industry

Powder Conveying: Sealed fans enable contamination-free pneumatic transfer of active powders.

Fermenter Aeration: High-pressure fans supply sterile air to bioreactors with ±2% pressure accuracy.

Product Core Advantages

Performance

✓ High Efficiency: Backward-curved blades improve efficiency by 15–20% over conventional models.

✓ Durable Materials: 316L stainless steel casing and impellers resist corrosion, lasting 3× longer.

✓ Low Noise: Dynamic balancing and silencers keep noise ≤75 dB(A).

Reliability

✓ Proven Technology: 13 patented technologies, including spin-formed construction, ensure failure rate <0.5% per year.

Application Cases

●Chemical Case: Pesticide Plant VOCs Treatment

Problem: Original fans corroded; exhaust efficiency <60%.

Solution: Custom YYHP high-pressure centrifugal fans with RTO incinerator.

Result: Airflow 12,000 m³/h; VOC removal >90%; annual electricity savings ≈ ¥180,000.

●Pharmaceutical Case: Lyophilized Powder Production

Requirement: ISO Class 5 cleanroom; airflow fluctuation <0.2 m/s.

Solution: Low-turbulence centrifugal fan arrays with smart VFD control.

Result: Suspended particles reduced 40%; passed EU GMP audit.

●Food Case: Seasoning Drying Line

Problem: Hot, humid environment caused fan fouling and downtime.

Solution: Titanium alloy impellers + self-cleaning jet system.

Result: Maintenance cycle extended from 1 week to 3 months; production +25%; moisture variance ≤0.3%.

Contact Us

Contact Yueyu Machinery

Get tailored fan selection advice, fast quotes, and custom engineering support. We serve global industrial clients with one-on-one technical service and dependable manufacturing.