Powder & Granule Solutions by Yueyu

What Drives Safer, Smarter Powder Conveying??

Powder and granule conveying serves chemicals, pharmaceuticals, food, plastics, and more, requiring safe and efficient transfer of bulk solids. Combustible dusts create explosion risks, demanding explosion-proof and anti-static fan designs. Different material properties call for precise airflow control and wear- or corrosion-resistant construction. Environmental policies and smart manufacturing are pushing systems toward lower energy use, higher reliability, and intelligent operation.

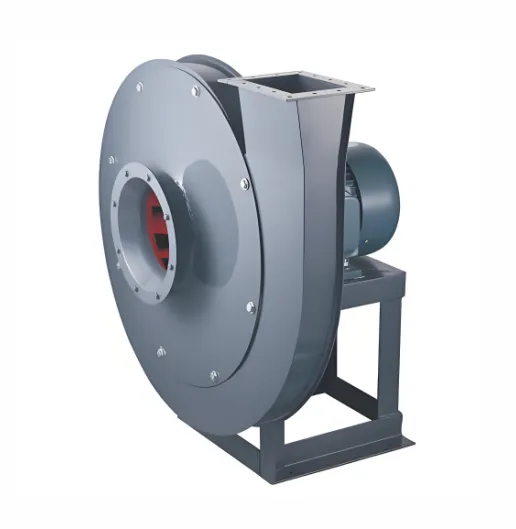

Yueyu Centrifugal Fans Meet Diverse Needs

● Pneumatic Conveying (Positive Pressure): Fans inject compressed air into pipelines to push materials over medium to long distances, suitable for high-density transfer such as plastic pellets.

● Vacuum Conveying (Negative Pressure): Fans create suction to draw materials into pipelines, ideal for multi-point intake and high dust-control requirements (e.g., YYDF centrifugal fans).

● Dust Collection & Environmental Control: Fans connect to dust collectors, such as bag filters, to remove airborne dust and maintain a compliant workshop environment.

● Production Process Support: Fans assist in processes like drying line airflow circulation and fluidized bed material suspension.

Product Core Advantages

✓ High-Efficiency Impellers: Optimized fluid dynamics increase pressure and airflow while reducing energy consumption.

✓ Wear & Corrosion Resistance: Thickened steel or 316S stainless steel impellers and casings handle abrasive materials like ore or metal scraps.

✓ Explosion-Proof & Sealed: Explosion-proof models with tight mechanical seals prevent leakage.

✓ Smart Adaptation: Variable frequency integration automatically adjusts airflow to match material load, preventing breakage or blockages.

Industry Application Cases

1.Plastic Recycling:Challenge: Lightweight film fragments can clog pipes; dust is flammable.

Solution: Yueyu custom mid-pressure explosion-proof centrifugal fans (YYMP) with cyclone dust collectors enable sealed negative-pressure transfer and dust collection, reducing workshop dust by 90%.

2.Pharmaceutical Raw Materials:Challenge: Active powders require contamination-free transfer and GMP compliance.

Solution: 304 stainless steel fans with HEPA filters provide fully sealed negative-pressure conveying, preventing cross-contamination and material loss.

3.Metal Scrap Recycling:Challenge: Abrasive metal shavings cause fan wear.

Solution: Fans with thick manganese steel impellers achieve three times the service life of standard models.

Contact Us

Contact Yueyu Machinery

Get tailored fan selection advice, fast quotes, and custom engineering support. We serve global industrial clients with one-on-one technical service and dependable manufacturing.