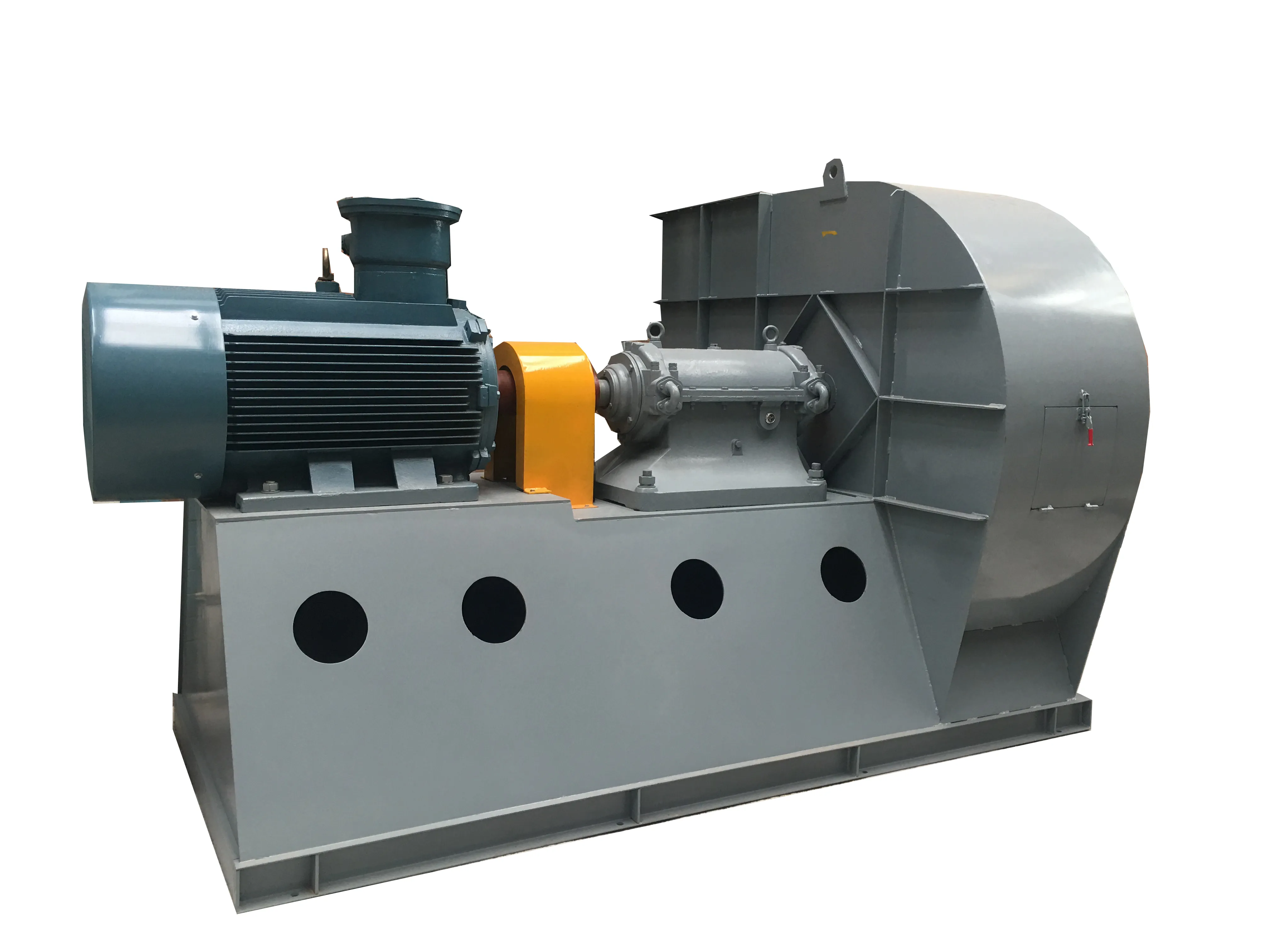

An industrial centrifugal fan is a mechanical device that utilizes rotating impellers to generate centrifugal force for gas transportation or pressurization. Its core component is the impeller, which draws gas axially and discharges it radially through high-speed rotation. It is suitable for industrial applications such as ventilation, dust removal, and exhaust.

I: Classification Methods

By Pressure Rating

Low-Pressure Fans: Pressure ≤ 980 Pa

Medium-Pressure Fans: Pressure 980–2942 Pa (e.g., factory ventilation, dust removal)

High-Pressure Fans: Pressure > 2942 Pa (e.g., industrial furnace air supply, material conveying)

By Drive Method

Direct-Drive: Motor directly connected to the impeller; compact structure.

Belt-Drive: Speed adjustable via belts; suitable for variable-speed requirements.

Coupling-Driven: Used for high-power equipment; high transmission efficiency.

By material method

Metal Fans: Stainless steel (corrosion-resistant), Carbon steel (general-purpose).

Corrosion-Resistant Fans: Fiberglass Reinforced Plastic (FRP), Polypropylene (PP); used in chemical, electroplating, and other corrosive environments.

Explosion-Proof Fans: Specially designed to prevent sparks; used in flammable/explosive areas (e.g., petrochemical plants, dust workshops).

By Application& Medium

General-Purpose: Standard ventilation (e.g., factory air exchange).

Special Scenarios: Boiler fans (heat-resistant); Dust removal fans (wear-resistant, anti-clogging); Explosion-proof/Corrosion-resistant fans (chemical, pharmaceutical);

Smoke extraction fans (fire protection systems).

II: Application Scenarios & Target Customers

- Industrial Manufacturing

- Ventilation & Cooling: Factory workshops, warehouses (Medium/Low-pressure fans).

- Waste Gas Treatment: Chemical plants, painting line exhaust (Corrosion-proof/Explosion-proof types).

- Material Conveying: Pneumatic conveying of powders/granules (High-pressure fans).

- Energy & Environmental Protection

- Boiler Combustion Support: Power plants, heating systems (High-pressure, heat-resistant fans).

- Dust Removal & Purification: Dust collection systems in metallurgy, building materials industries.

- Waste Gas Treatment: Environmental engineering (e.g., fans for desulfurization towers).

- Construction & Public Facilities

- Fire Smoke Extraction: Subways, shopping malls (Heat-resistant fire fans).

- Tunnel Ventilation: Highway/Railway tunnels (Mixed-flow or jet fans).

- Central Air Conditioning: Commercial buildings (Low-noise centrifugal fan units).

- Specialized Industry Customers

- Chemical/Pharmaceutical Companies: Require customized explosion-proof/corrosion-resistant fans (e.g., 316 stainless steel).

- Food Processing Plants: Require sanitary-grade stainless steel fans (easy to clean, corrosion-resistant).

- New Energy Vehicles: Special explosion-proof stainless steel fans for coating drying processes.

III: Selection Recommendations

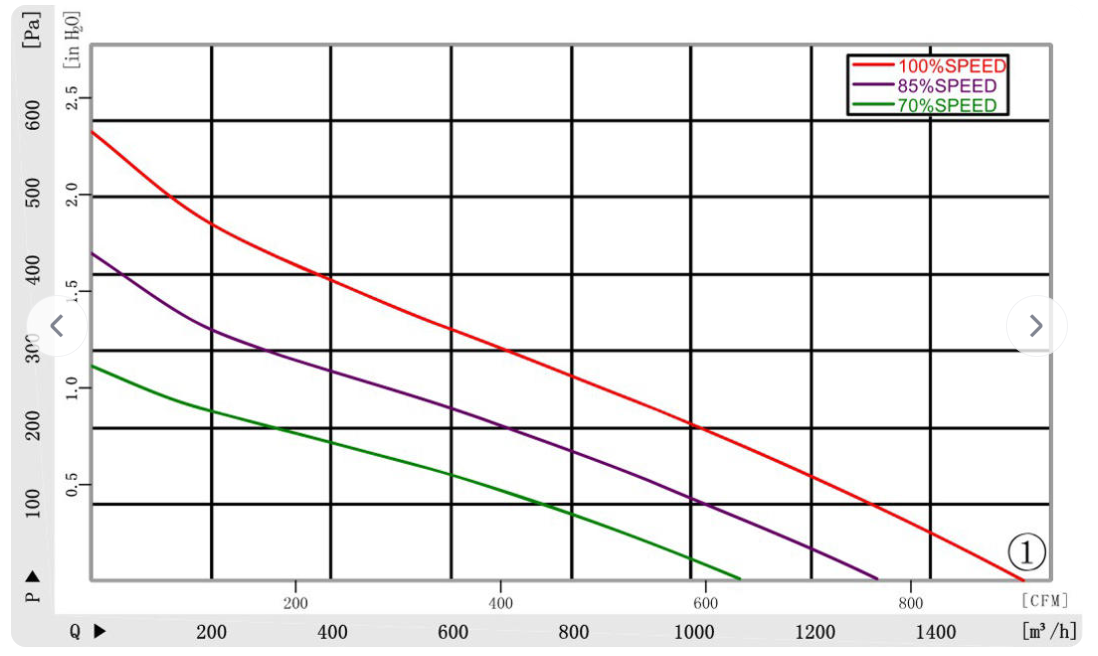

- Define Required Parameters: Airflow volume, pressure, medium characteristics (temperature, corrosiveness).

- Match the Scenario: Select explosion-certified fans for hazardous areas; choose heat-resistant models for high-temperature environments.

- Optimize Cost: Carbon steel fans suffice for civilian use; prioritize FRP/stainless steel for highly corrosive environments.

Custom Solutions from YueYu Machinery

With years of expertise in fan manufacturing, Yueyu Machinery provides centrifugal fans in all major drive configurations to suit various industrial applications.

Advantages of Yueyu fans include:

• Energy-efficient design, reducing power consumption by up to 15%–20% compared to standard models.

• Low-noise operation with sound levels as low as 75 dB.

• Fully customizable solutions, including drive type, blade angle, and high-temperature or corrosion-resistant materials.